Let me stop here and say the roof is by far the hardest part of the build. First, you’re up on a ladder, which I hate. You’re also dealing with long rafter boards, which are hard to move around. Like most of this construction, the roof is a 2-person job, with one person on a ladder and one person just cutting and handing them things.

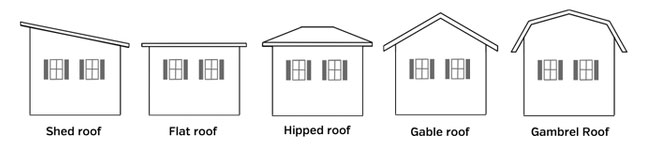

Rafters are the bones of your roof. During the design phase you should have thought about types of roofs.

I picked a “shed” roof, which is flattish type roof with a low roof angle. If you get snow, I wouldn’t pick a shed style roof design. I choose a shed roof because it’s easy to build and because I didn’t use an attic space. I have really high ceilings on one side--12-foot ceilings make the room feel much larger.

The construction of a roofing system depends on the style of roof, so this will only explain how I built my roof. Rafters support the roof. Mine hang over the front and back by 1 foot. Since my workspace is 12 feet, each board is 14 feet long. I used 2’x6’ pressure treated lumber, too. It’s about $1.50 more per board, but we only used about 20 boards so I went with pressure treated.

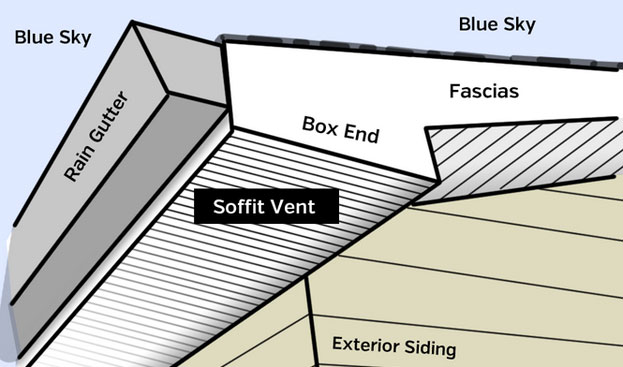

Where the roof hangs over the walls, that’s called the ladder. The ladder contains a vented area called the soffit, which vents your attic’s trapped heat. You’ll notice houses that have a roof ridge will have a roof ridge vent to let trapped heat and humidity escape. My workshop doesn’t have an attic, so we placed “baffles” in between the ridges to let the under roofing heat escape.

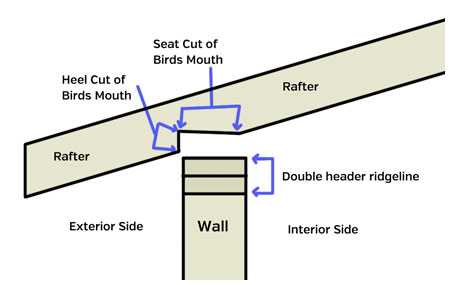

Rafters have metal brackets to fasten them down. Also, there are notches cut into each rafter to allow it to sit on top of the wall. These notches are tricky to cut, and they’re called a “bird’s mouth.”

On top of the rafters sits more sheathing, and again I used OSB sheets. Like the wall sheathing, you leave little spaces so the sheets can expand during weather changes. Roof sheathing gets little metal spacers to help you with the proper spacing.

On top of the roof sheathing you tack down tarpaper or roof felt. I used roof felt since it was only $50 more for a build this size and lasts for 15 years longer than tarpaper.

The roofing system install depends on what you buy. I wanted a metal roof, so I called a local place that bends their own roofing panels and sells them to the public. I told them what I was doing, showed them a drawing and they got my order processed. My metal roof cost $425 (metal panels, screws, drip edges and felt paper). I needed a trailer to haul the 14-foot metal panels.

My roof consists of 3-foot wide sheets of metal roofing. You screw them into the rafters, OSB and thru the roofing felt with screws that have rubber washers on them to seal the hole shut. Since the roofing system install changes based on the type of roof you get, I won’t go into details. I’ll just say you’re basically layering flashing, drip edges, etc. to work with gravity to keep the water out of your building. Here’s more information on roofing installations.

Once your roof is on, your walls are wrapped, and windows and doors are in, your building is called “dried out.” This means your building is rainproof (hopefully).

The word soffit is derived from the French word for "formed as a ceiling" and the Latin term for "to fix underneath.” It is the exposed surface beneath the overhanging section of a roof eave. It can also refer to the horizontal underside of similar architectural structures such as an archway, a staircase or a ceiling.

Part of the function of the soffit is to assist in ventilating the attic. The soffit typically features a plain design with small holes that provide air circulation. The air from the soffit cycles to the vents to draw heat and moisture away from the house. This is a highly important function because moisture in the attic can develop rot in the sheathing and rafters.

Most soffits are made from vinyl, an effective material for withstanding the degradation that comes from heat and moisture exposure. This is especially important considering that the soffit can be easily exposed to moisture due to unkempt gutters and wet weather conditions.

The primary role of the fascia is to act as a layer between the edge of the roof and the outdoors, and is meant to protect the wooden board against water damage that can occur during certain weather conditions.

Aside from its functional role, the fascia also plays a very important aesthetic role since it creates a smoother, more even appearance for the edge of the roof. In addition to protecting the wooden board from water damage, the fascia protects the entire roof and the interior of the house from weather damage by blocking its entrance to the home. The majority of homes will feature a fascia board, but some older home styles lack this component.